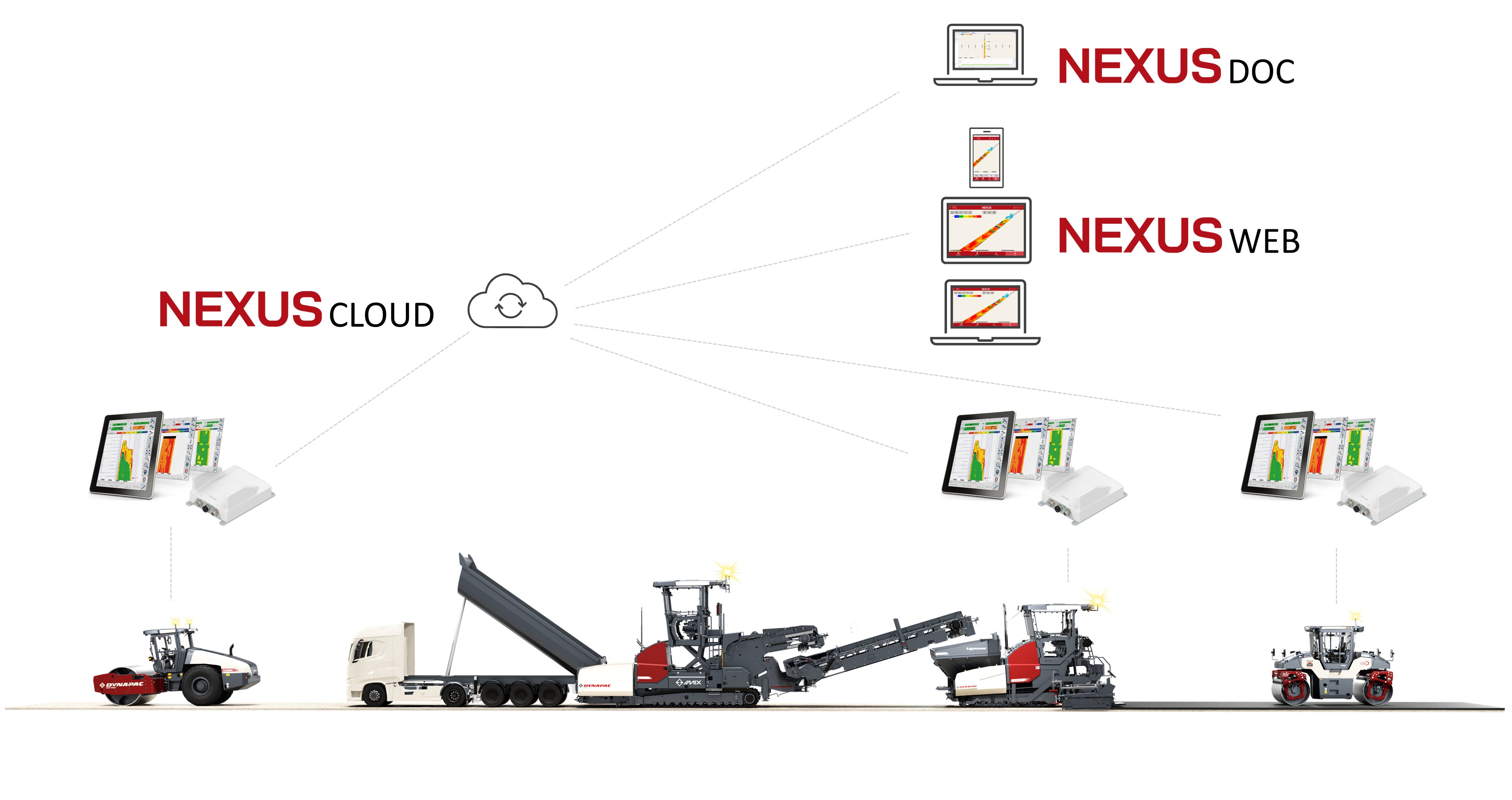

Nexus ensures that every data point from your job site is captured, synchronized, and accessible in real time — all in one centralized cloud platform. Whether it’s compaction values, material temperatures, or machine activity, Nexus continuously streams raw data from connected machines to the Nexus Cloud, eliminating data gaps and ensuring traceable project documentation. Even in areas with poor reception, data is stored locally and synced automatically when the connection is restored.

No matter what machines you operate — soil rollers, asphalt rollers, pavers, or feeders — Nexus is ready. Thanks to a truly modular and brand-agnostic hardware setup, the same Nexus Connectivity Kit can be used across your entire fleet. Just add a machine-specific Prep Kit, and you’re ready to go. This flexibility makes Nexus the ideal investment for mixed fleets or growing equipment pools, significantly reducing complexity and cost.

Operators can focus on the job, not the tech. Nexus is built around simplicity and automation: once the machine ignition is turned on, the system boots, connects, and begins recording — no buttons to press, no processes to remember. The system auto-detects machine type and activates the correct setup, reducing human error and training time, while boosting overall reliability across job sites.

With rugged quick mounts, intuitive connectors, and magnetic antennas, setting up Nexus each day takes minutes — not hours. The hardware is robust enough for harsh construction environments, and software setup is streamlined through cloud-connected web and desktop apps. Everything from initial setup to live tracking and post-job analysis is designed to get your team operational, fast.

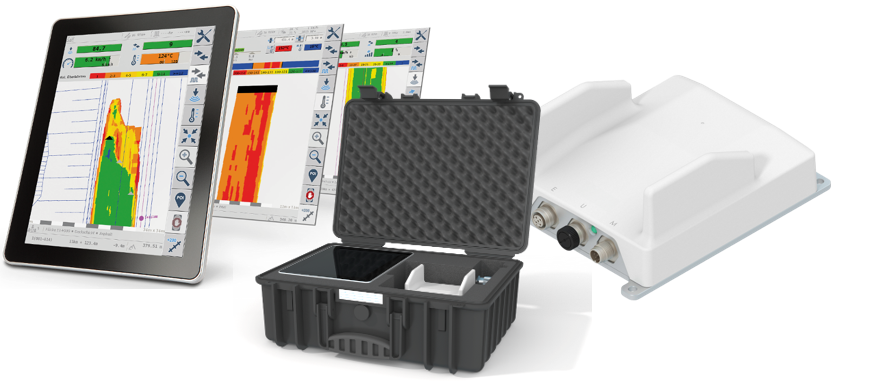

At the heart of the Nexus platform lies the Connectivity Kit — your all-in-one hardware hub for digital job site operations. Housed in a rugged, transport-ready case, it includes the Nexus Display tablet and a high-performance RTK & 4G antenna. This kit connects directly to your machines and ensures uninterrupted data flow, even in areas with weak reception. With plug-and-play simplicity, the Connectivity Kit can be moved from machine to machine, delivering maximum flexibility on site.

Each machine — whether it's a soil roller, asphalt roller, paver, or feeder — can be equipped with a dedicated Prep Kit. These kits include everything needed for Nexus integration: harnesses, link modules, display connectors, and pre-installed mounts. For example, asphalt rollers include temperature and compaction sensors; pavers get screed width and thermal mapping readiness. Prep Kits make your machines Nexus-ready with minimal effort and no technical guesswork. If your Dynapac machines runs Open Interface it is even more simple: Connect the link module to the OpenInterface and enjoy a seamless communication with all integrated sensors to avoid additionla hardware fitting.

You don’t need brand-new equipment to go digital. Nexus supports older machines and third-party brands through special retrofit kits that include sensors, adapters, and smart mounting solutions. This extends the life of your existing fleet and enables seamless data capture across mixed machine environments — a critical feature for rental fleets or contractors working with varying OEMs.

The central brain of the ecosystem, Nexus Cloud is a secure, real-time platform that synchronizes all machine and job data. It allows everyone involved — operators, site managers, office staff — to access consistent, up-to-date information from any location. With cloud-based project storage, your data is always where you need it, when you need it.

Designed for use in the field or on the go, the Nexus Web App offers a lightweight interface to set up jobs, assign machines, define working layers, and monitor live site performance. It includes a live map view of all equipment, the ability to create Points of Interest (POIs) on the fly, and centralized control of machine targets such as pass counts or compaction goals. It's the perfect tool for dynamic, real-time collaboration.

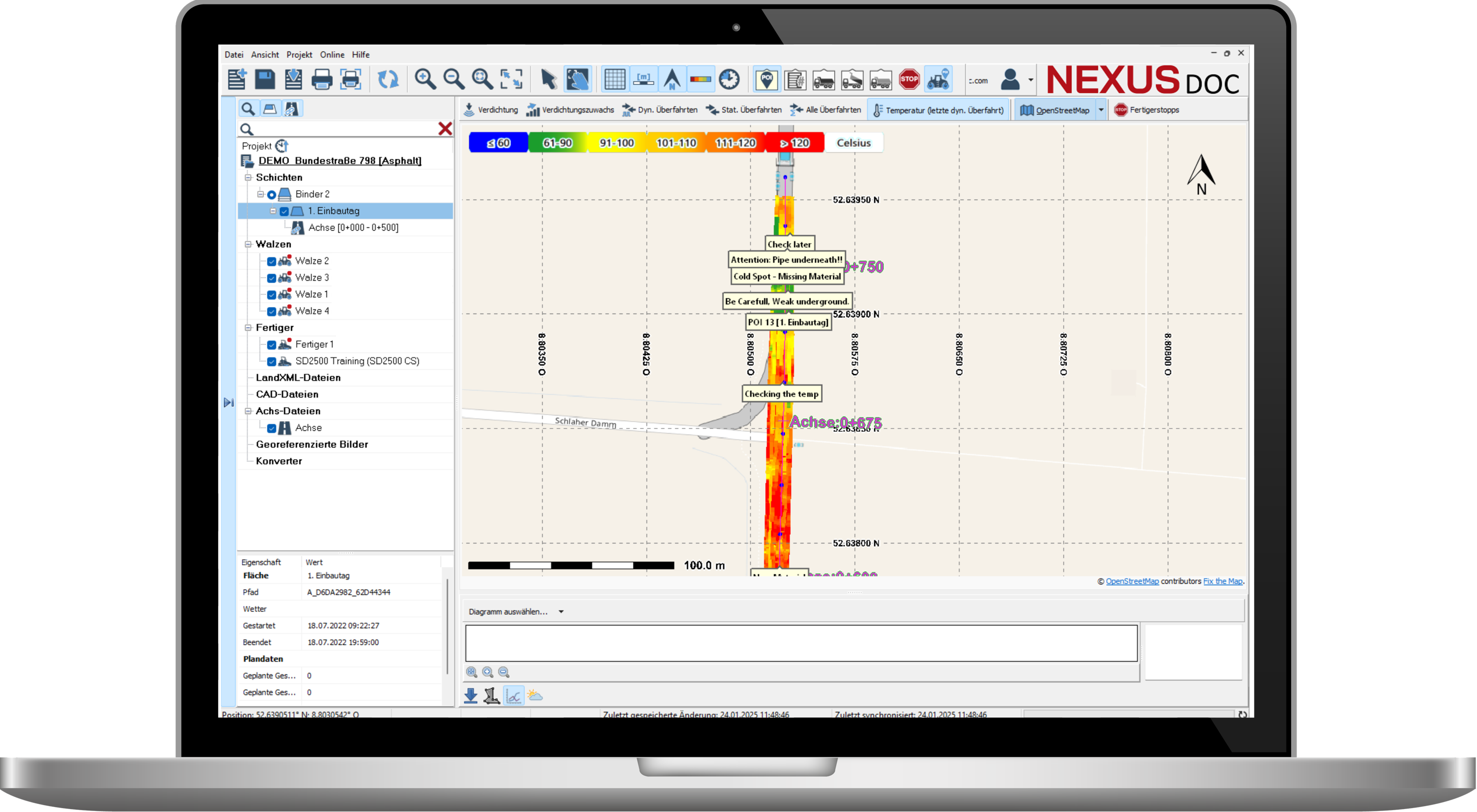

For detailed planning and in-depth analysis, Nexus Doc offers a powerful desktop experience. Import CAD plans, define project parameters, configure machine behavior, and analyze job data with customized filters. The app also allows users to generate tailored reports (.pdf, .xlsx, .json) to share with stakeholders or clients — offering transparency, compliance, and traceable documentation from start to finish.

With Nexus, soil rollers become intelligent, data-driven machines. The system logs both static and dynamic passes, calculates precise compaction values (EVT), and detects jumping or inconsistencies in vibration. Operators gain immediate feedback, while supervisors access live performance metrics from anywhere.

Whether static or dynamic, asphalt rollers fitted with Nexus provide a full spectrum of performance data. Dual compaction sensors monitor drum behavior, while spot temperature sensors capture thermal data across each pass. This enables smarter compaction strategies, better material handling, and higher quality results.

Nexus enhances paving operations with thermal mapping, live screed width tracking, and truck handover monitoring. Optional weather stations capture ambient conditions, helping optimize timing and temperature windows. All data is linked through the paver’s CAN-bus for precision tracking and analysis.

Feeders can be wirelessly connected to pavers via Bluetooth, sharing real-time truck and material flow data. Truck Recognition Sensors automatically log docking, unloading, and departure, while Material Flow Sensors track core temperature as asphalt is delivered. Together, they close the loop in material logistics and support more consistent paving outcomes.