Compaction Redefined

With a Seismic Soil machine you benefit from, increased productivity, energy and cost efficiency as well as operator comfort and simplicity. The Patented Seismic innovation by Dynapac is unique and is the only system on the market that is completely automatic with no need for additional operator training.

Excellent Operator Comfort

The machine operates at a lower noise level and transmits fewer vibrations to the cab, thanks to reduced frequency levels. This results in a more pleasant experience for the operator, allowing you to enjoy your workday in a quieter, smoother, and more comfortable cab.

Select and go

Starting a machine with Seismic is incredibly simple, as Seismic is automatically activated by default. Just pick high or low amplitude. That’s it. You’re ready to roll.

Thanks to lower frequency vibrations, the improvement is evident both inside the cab and in the area around the machine. You get a calmer, more comfortable workspace that enhances both focus and overall operator well-being.

Seismic Soil

How the System Works

The system provides real-time monitoring and continuously adjusts the frequency automatically based on the material. No additional training is required and no risk of getting the compaction settings wrong. By working in harmony with the material being compacted, it significantly reduces issues like bouncing and aggregate crushing. This fully automatic compaction process eliminates operator guesswork, ensuring optimal performance for any material or layer thickness.

Reduces Wear and Tear

Thanks to Seismic and the optimised frequency adjustments, the vibration powertrain and drum shell are exposed to less stress and wear compared to conventional compaction. This, in turn, means a longer life of the vibration mechanism and related hydraulics. On top of this, Dynapac's already durable and thick drum shells will last even longer, maximising the drum lifetime.

Marked components benefit from extended lifetime enabled by Seismic Soil:

Scientifically Proven

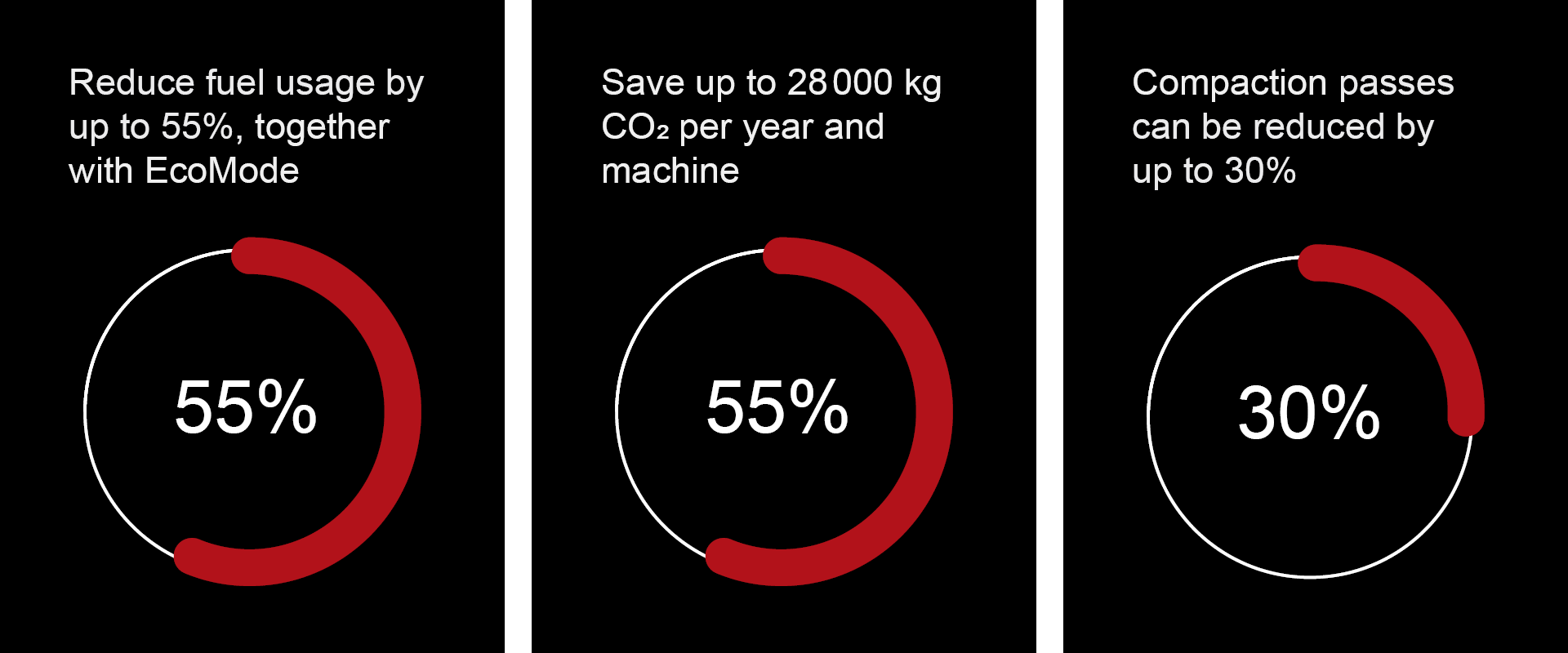

With Seismic Soil, operators can reduce the number of compaction passes by up to 30%, delivering faster results with lower fuel use and reduced operating costs.

These benefits are backed by repeated testing, including studies from KTH Royal Institute of Technology and VTI (Swedish National Road and Transport Research Institute), which confirm that Seismic Soil technology increases compaction efficiency while also lowering environmental impact.

Seismic Delivers More

EcoMode

With the EcoMode setting enabled, the machine operates at the lowest possible RPM without compromising compaction quality. The machine automatically idles after 10 seconds in neutral, significantly reducing engine RPM. This feature does not interfere with the general workflow or operation of the machine and ensures instant start-up after idle mode.

Compaction Meter

The Dynapac Compaction Meter provides real time stiffness measurements to ensure optimal compaction. The compaction meter can present three unique values for the operator, CMV, EVIB1 and EVIB2. Seismic Soil uses the Compaction Meter Sensors to calculate the frequency adjustment.

Active Bouncing Control

When the soil becomes highly compacted, it can no longer absorb additional energy, leading to harmful bouncing. The system operates by first alerting the operator when bouncing is detected. Subsequently, the machine automatically disables vibrations and notifies the operator to reduce the amplitude, ultimately resulting in the cessation of vibrations.