Dynapac soil compactors aren’t just engineered for though conditions, they are proven in the field. Operators describe them as robust machines with minimal maintenance needs, delivering reliability shift after shift.

On a late summer day at a highway construction site in northern Germany, the KEMNA team is preparing for operation. However, today marks a special occasion: the new Dynapac XD25 110C is operating on-site for the very first time.

Dynapac India received the “Top Exporter for the year 2023-2024 for Medium Enterprise” at the 56th Engineering Export Promotion Council of India National Award from Shri Piyush Goyal – Hon. Miniter of Commerce and Industry, Govt of India held at Vigyan Bhawan, New Delhi on September 8, 2025

Ridderkerk/Amstelveen, Netherlands – In a groundbreaking milestone for sustainable road construction, the all-electric SD25 80C e, the first paver of the highway class to be fully electrified, has successfully completed its first on site operation.

.png)

Follow us on Instagram, LinkedIn, YouTube and Facebook for quick updates and exclusive content from across the world of road construction.

The Future of Road Construction Technology: The Dynapac SD1800W e Impresses at Höhler On February 28, 2025, a significant milestone was achieved in German road construction: Our fully electric road paver, the Dynapac SD1800W e, was successfully put into operation at Höhler – a first in Germany!

Join us at BAUMA 2025 and discover the latest innovations shaping the future of the construction industry.

SMT is proud to announce a strategic partnership with Dynapac, a leading global provider of road construction equipment. This collaboration will extend across SMT entire footprint in Africa, covering 17 markets in West and Central Africa.

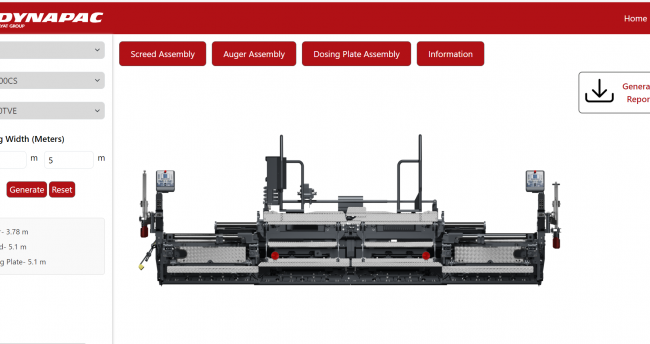

An innovative tool designed to significantly simplify the working width configuration process for paving professionals.

Dynapac South Africa celebrates the launch of the Rhino soil compactors as well as the company's 90th anniversary together with dealers and customers.

This October, Dynapac Italy made a significant impact at the Asphaltica Exhibition in Bologna, where tradition met innovation in a showcase that captured the attention of industry professionals. Representing the heritage of the brand was the SD2500WS paver, a flagship model that continues to lead the market.

If you want to check out all the Dynapac news items click here.

To unlock extra Dynapac news items you have to log in with your MyDynapac account first.